- Product Lines

-

-

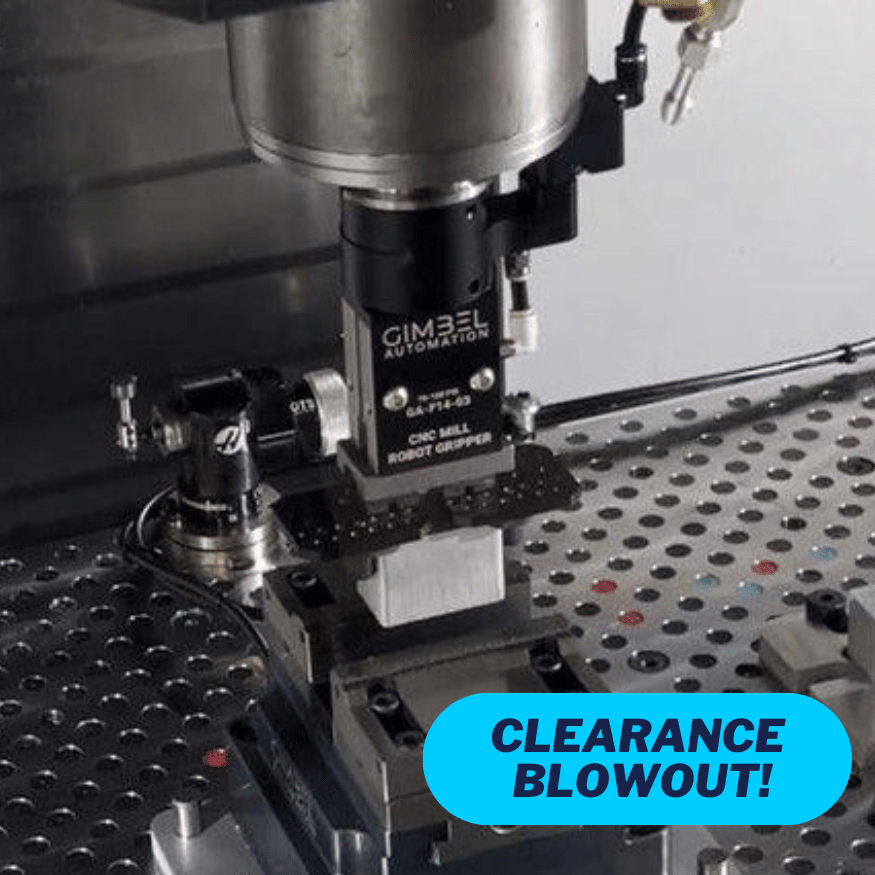

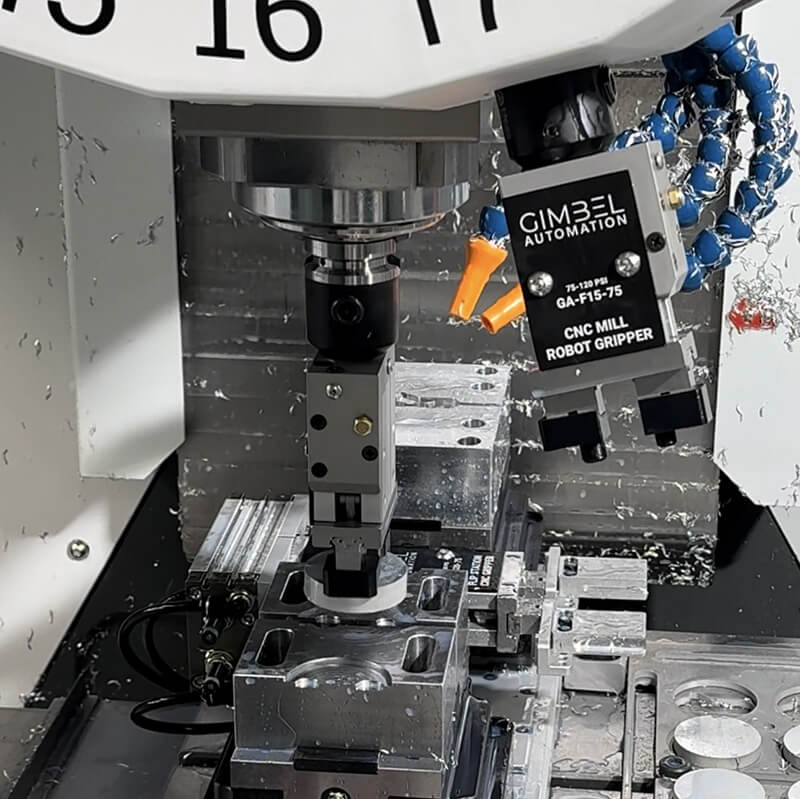

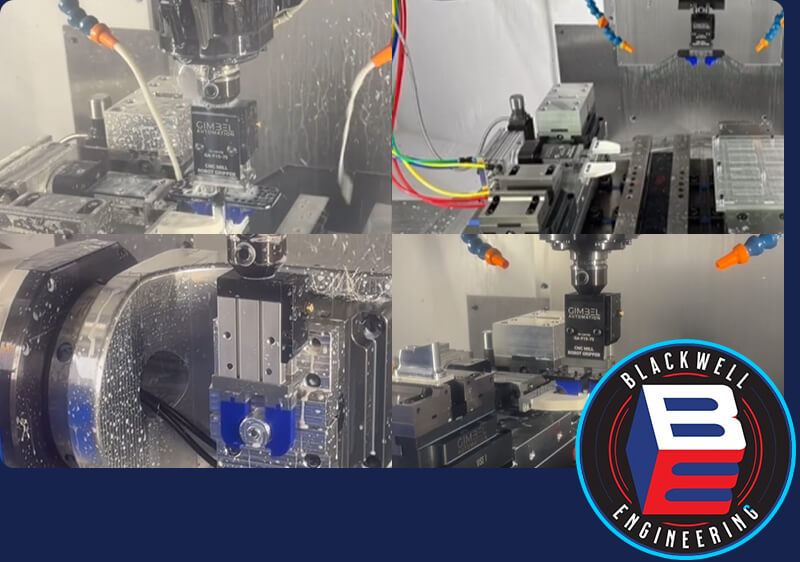

Air CNC GimGrippers™

Universal for Through air machines

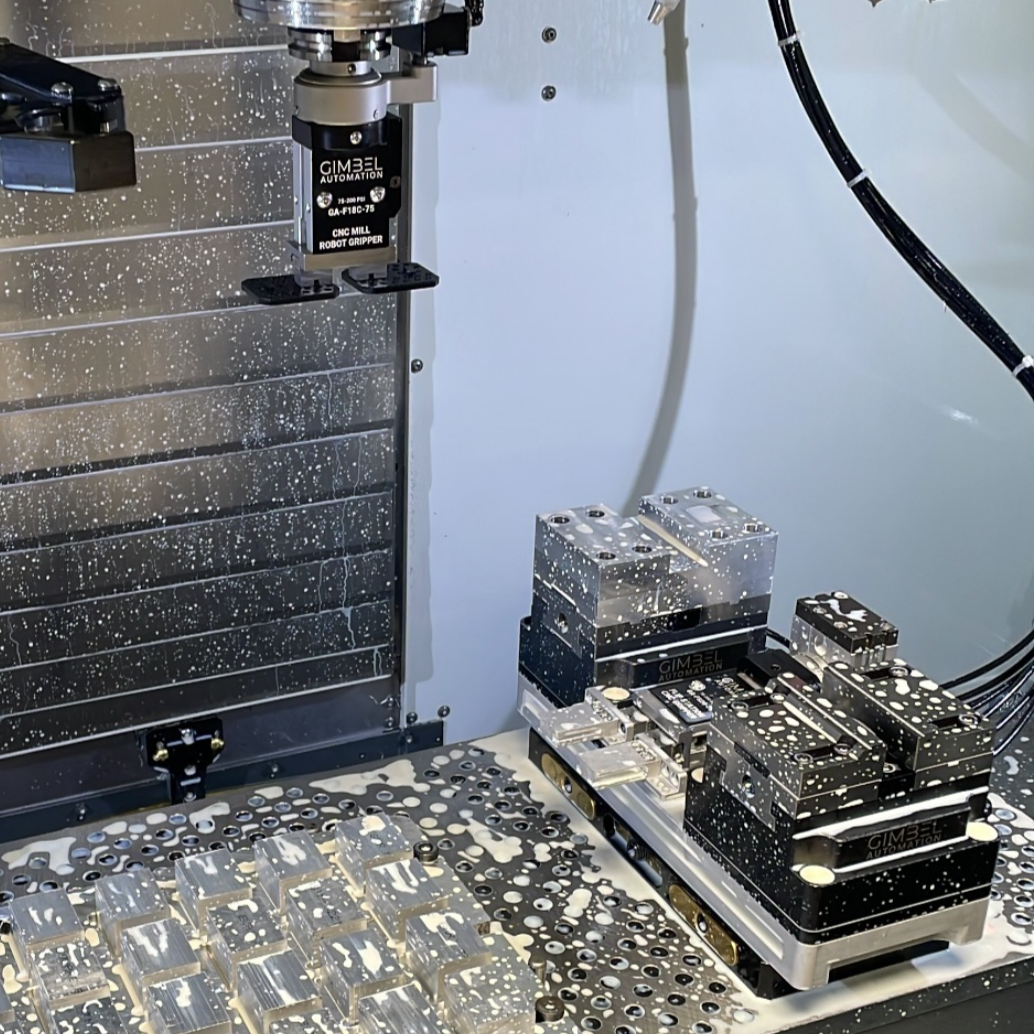

Coolant CNC GimGrippers™

Universal for TSC machines

FloLink™ CNC GimGrippers™

FloLink™ grippers that allow spindle orient

GimVac™ Vacuum Grippers

Load parts using vacuum

GripFlipGrip™ Modules

Easy two-op single cycle automation

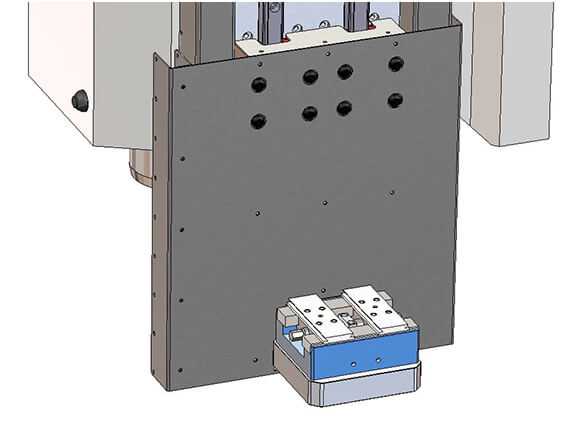

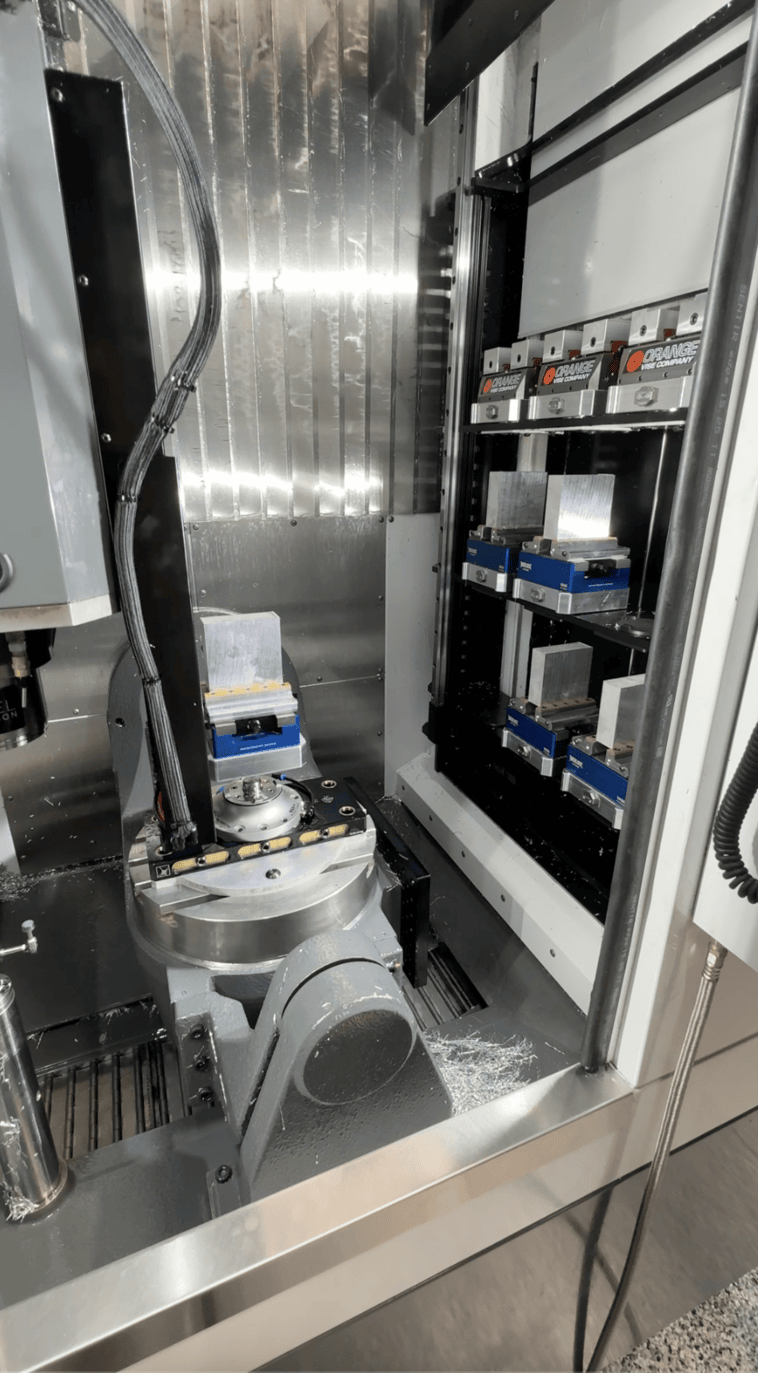

QuickFlip180™ CNC Station

Flip parts for two-op automation -

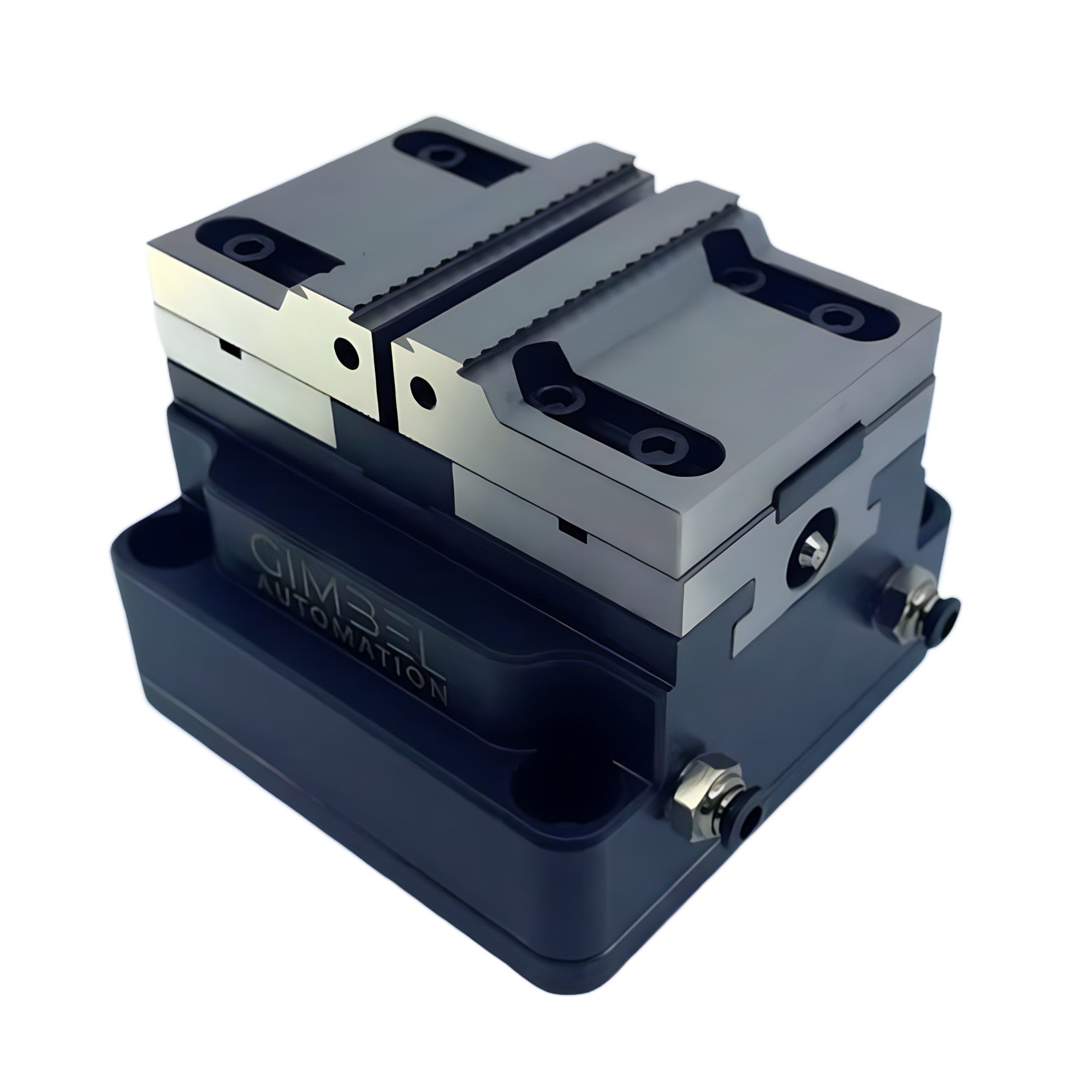

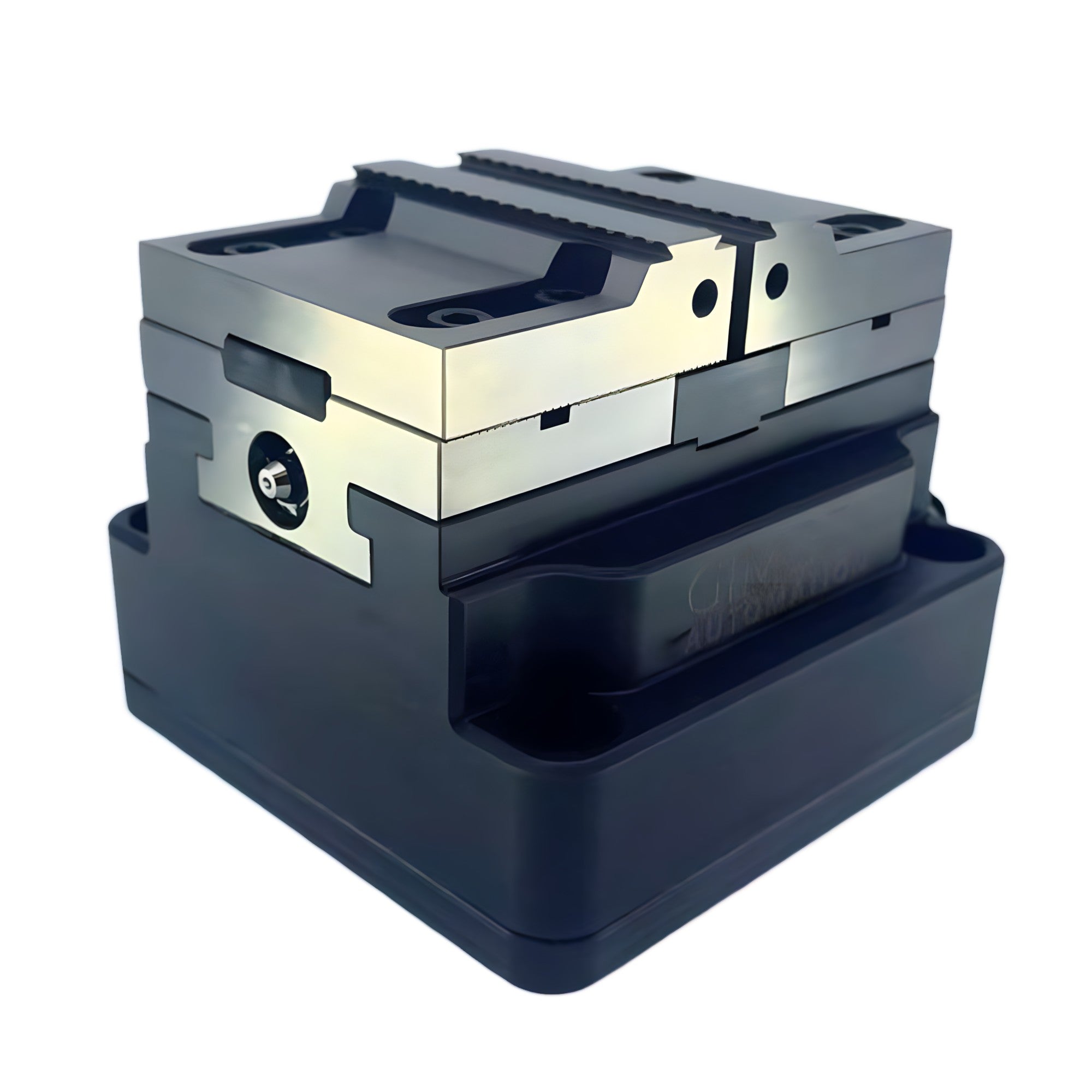

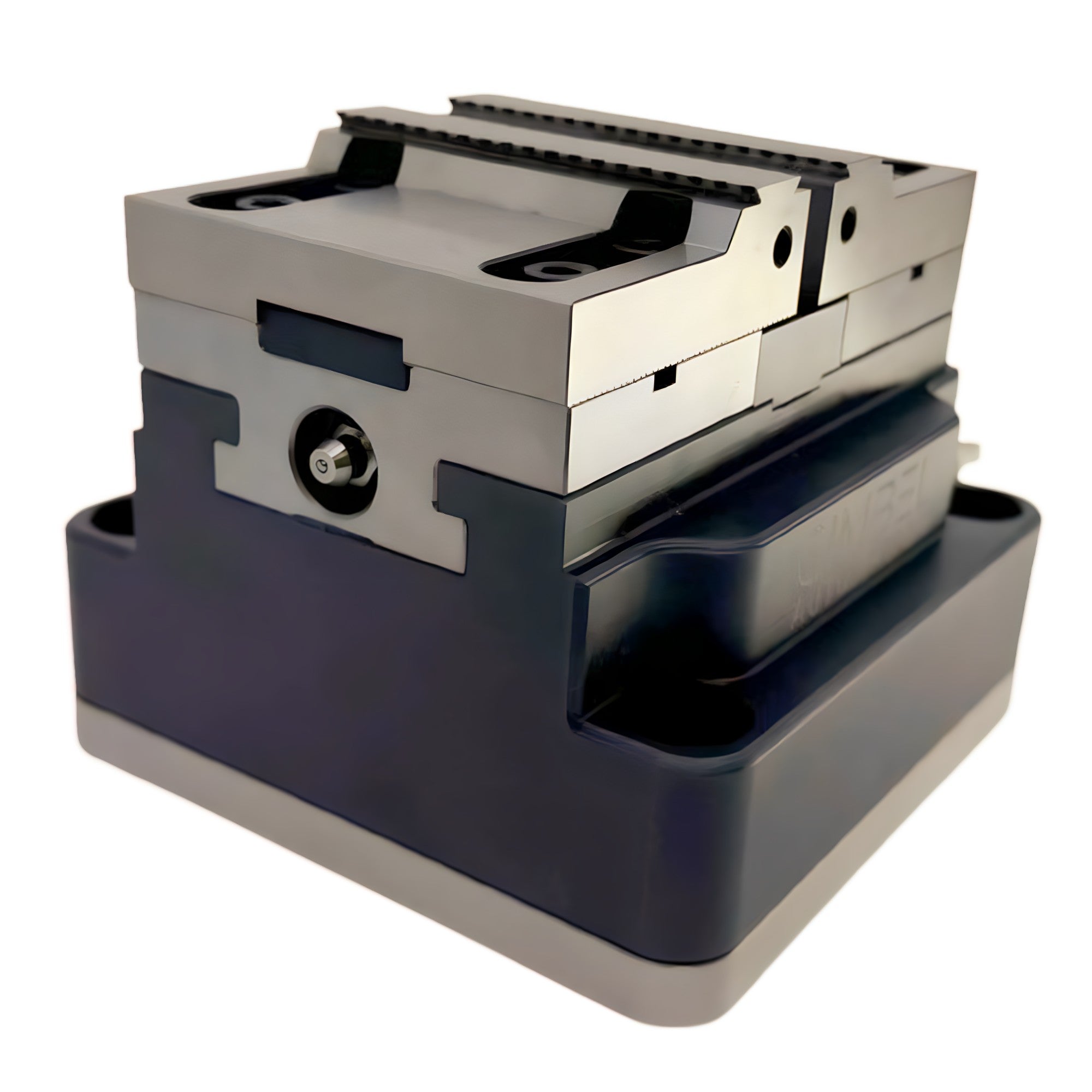

75mm Air AutoVise™

Compact pneumatic self-centering vise

Rotary Air AutoVises™

CNC pneumatic vise for 4 & 5th axis

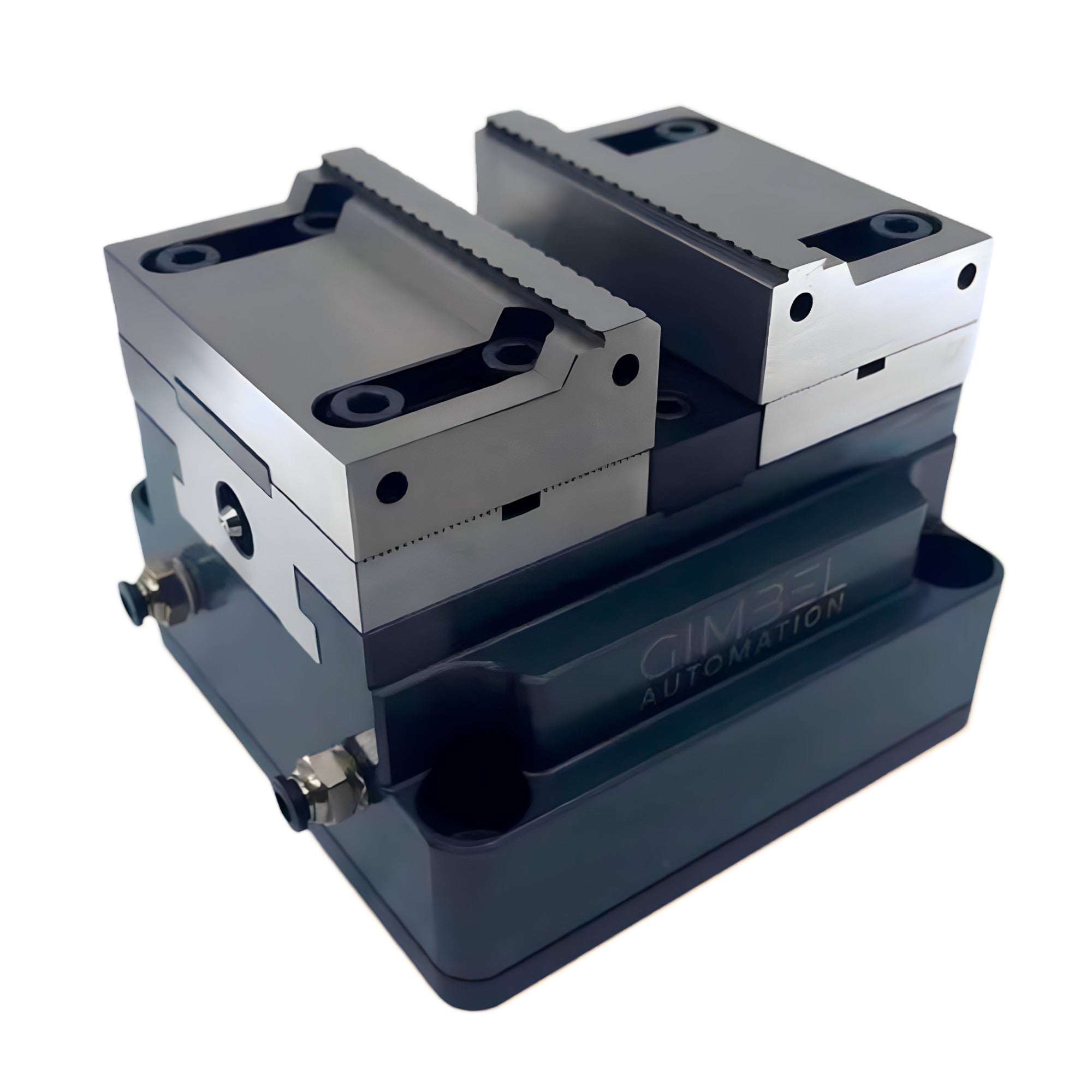

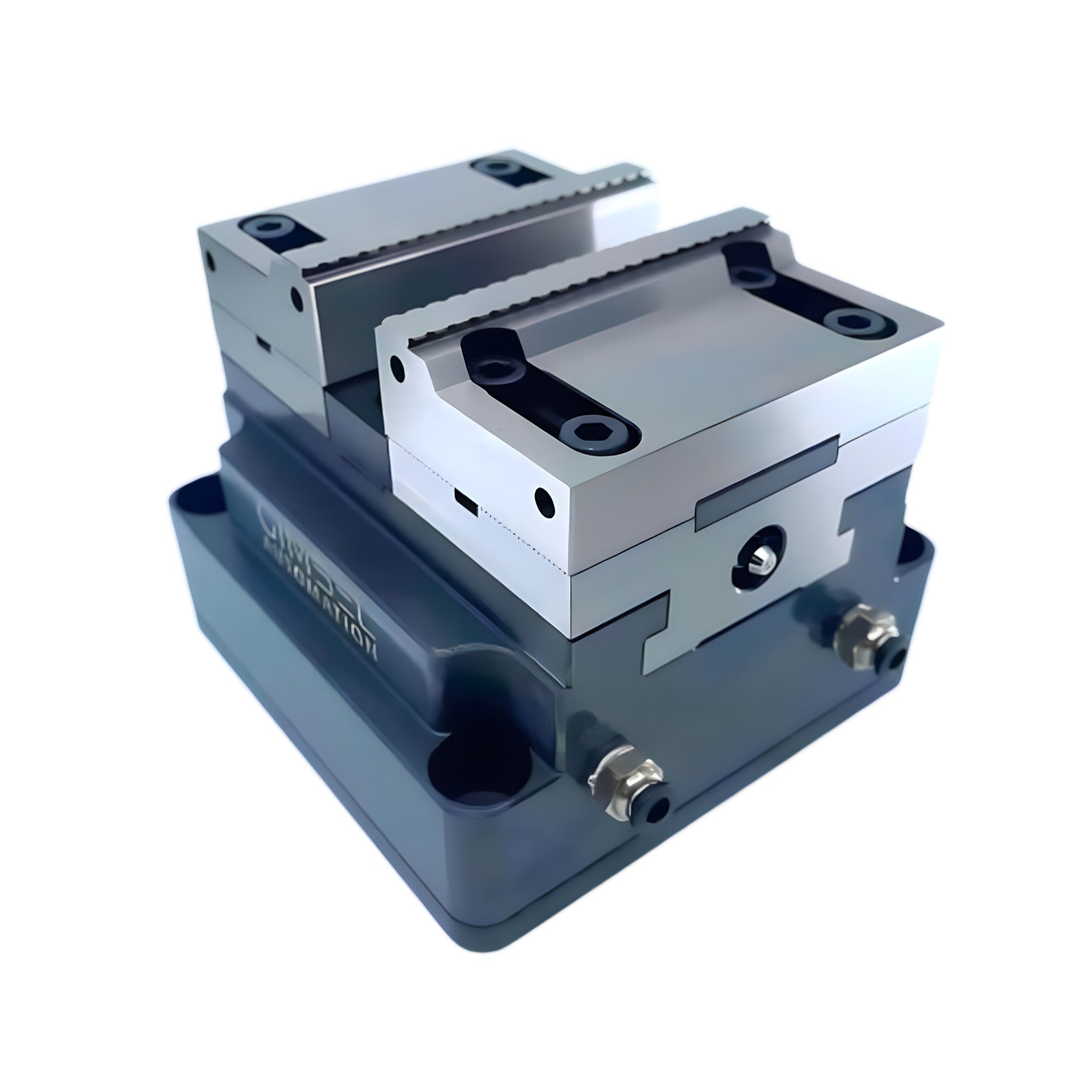

100mm Air AutoVise™

Mid-sized pneumatic self-centering vise

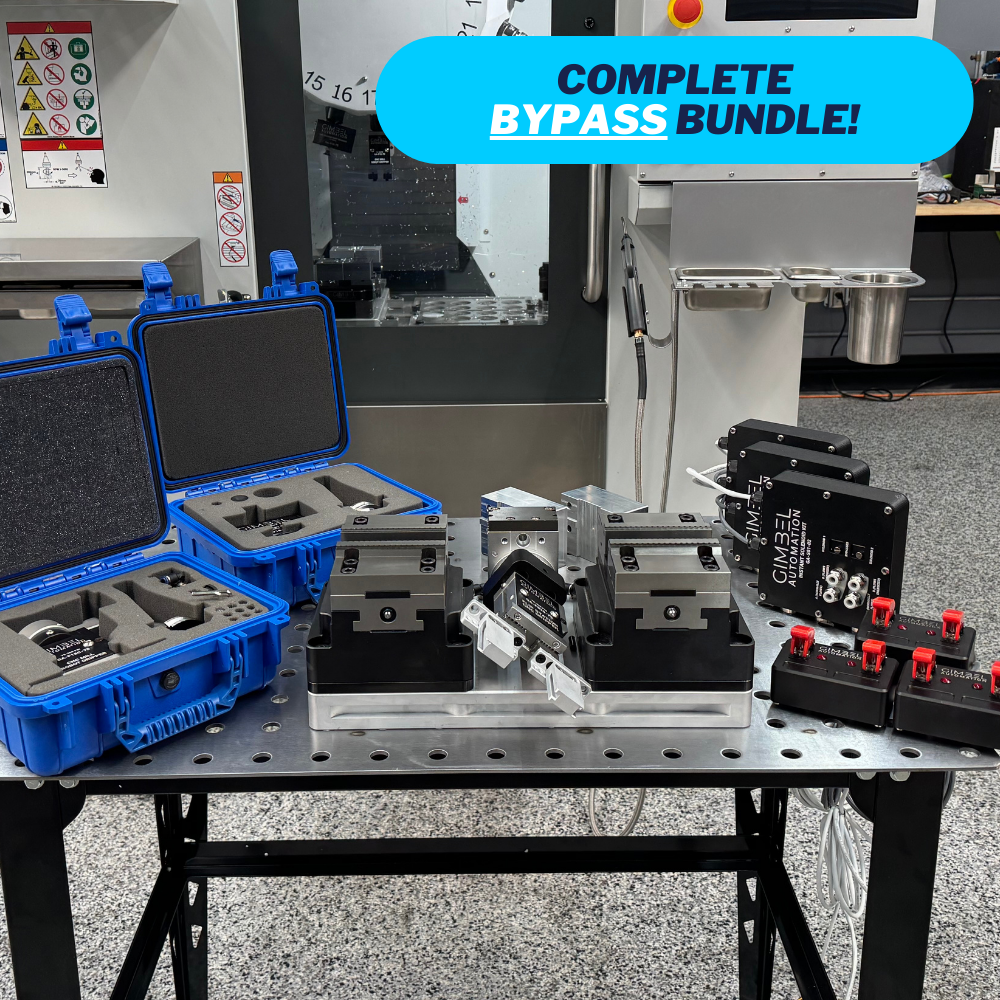

GripFlipGrip™ Modules

Easy two-op single cycle automation

150mm Air AutoVise™

Extra large pneumatic self-centering air vise

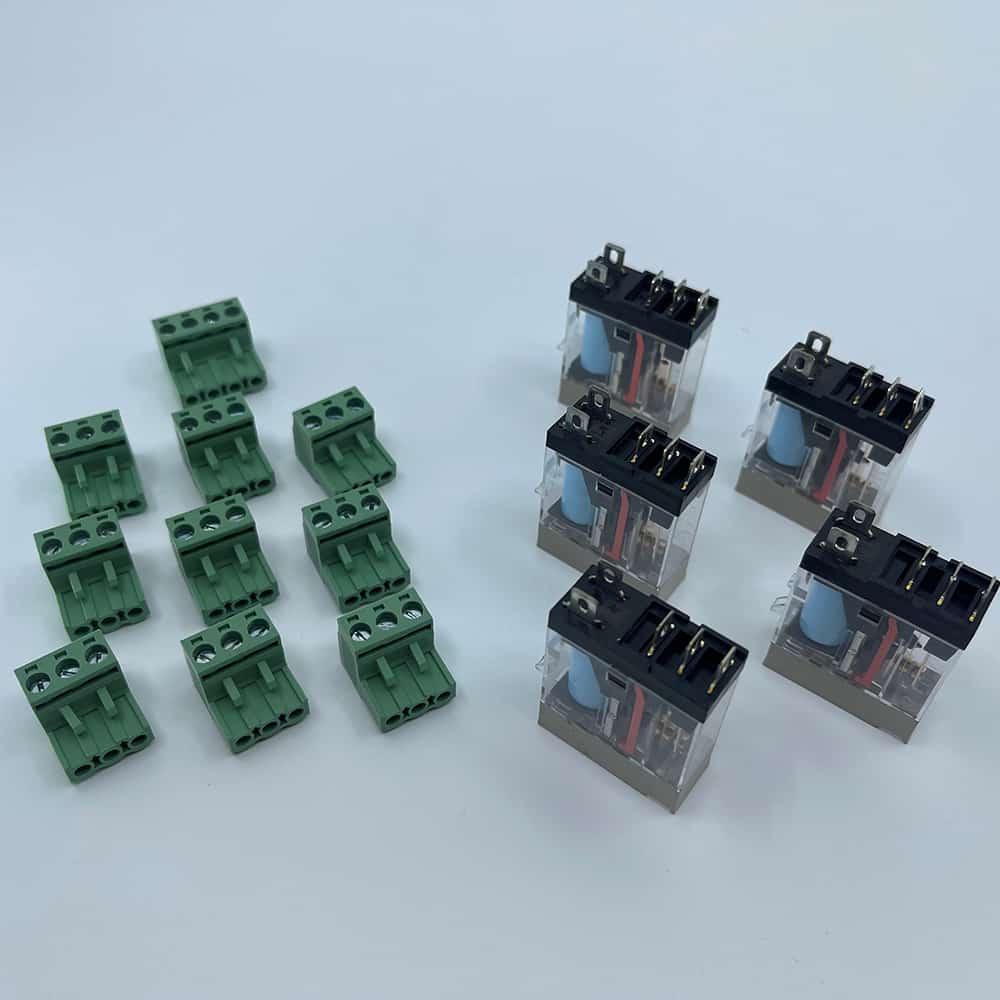

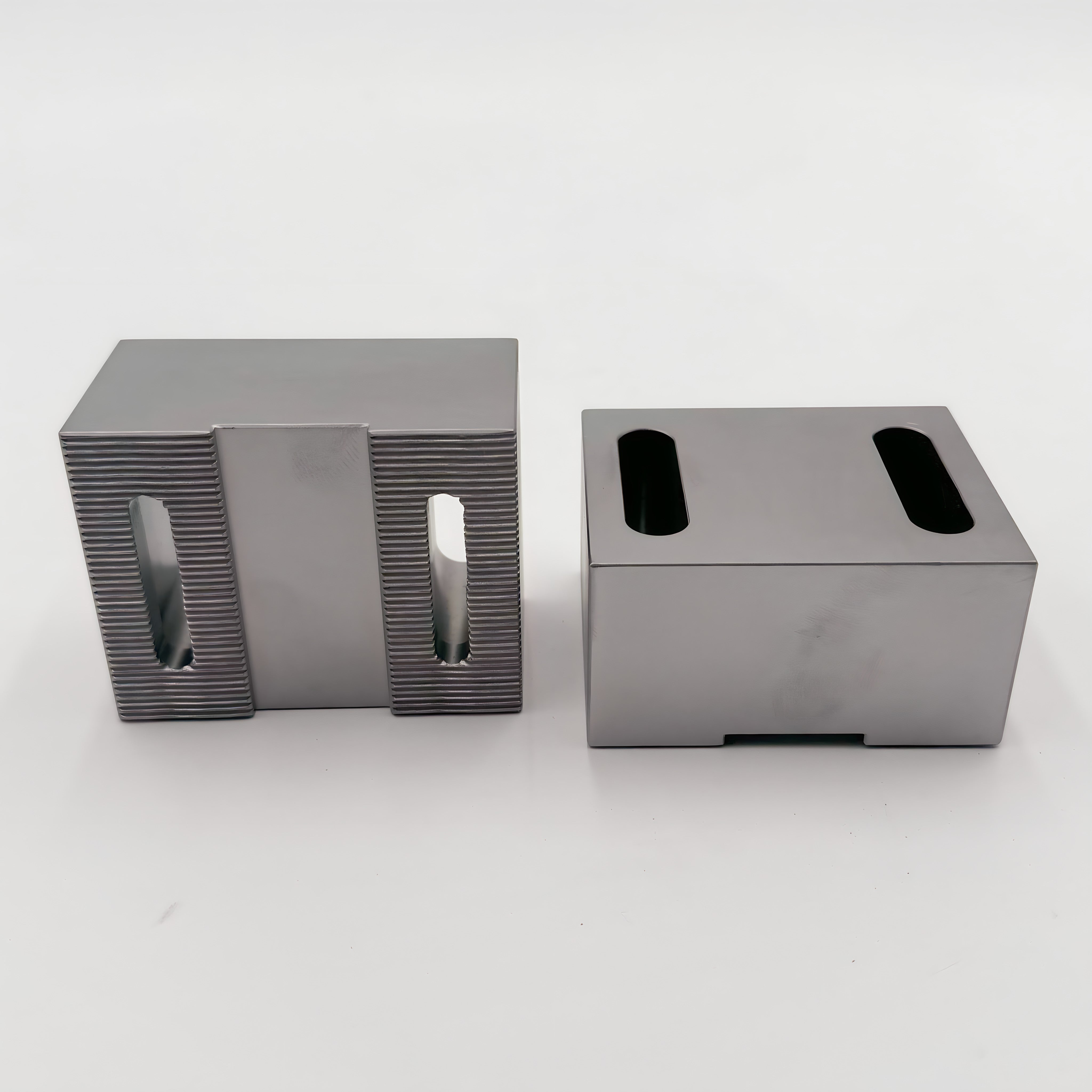

Hard & Soft Jaws

Jaw options for your gimbel air vises -

-