Explore AI Summary

What is a Finger for Air Grippers?

Fingers for Air Grippers or Coolant Grippers are the attachments that grab the part or component to be manipulated.

Fingers for Grippers (Air or Coolant) can be modular Universal Fingers, 3D printed, machined from billet, or made for a specialty application.

What is a Gripper Finger?

A Gripper Finger for an Air or Coolant Gripper is the attachment that grabs the component to be manipulated. Gripper fingers can be modular Universal Fingers, 3D printed, machined from billet, or made for a specialty application.

The Types of Gripper Fingers

1. Universal Gripper Plates

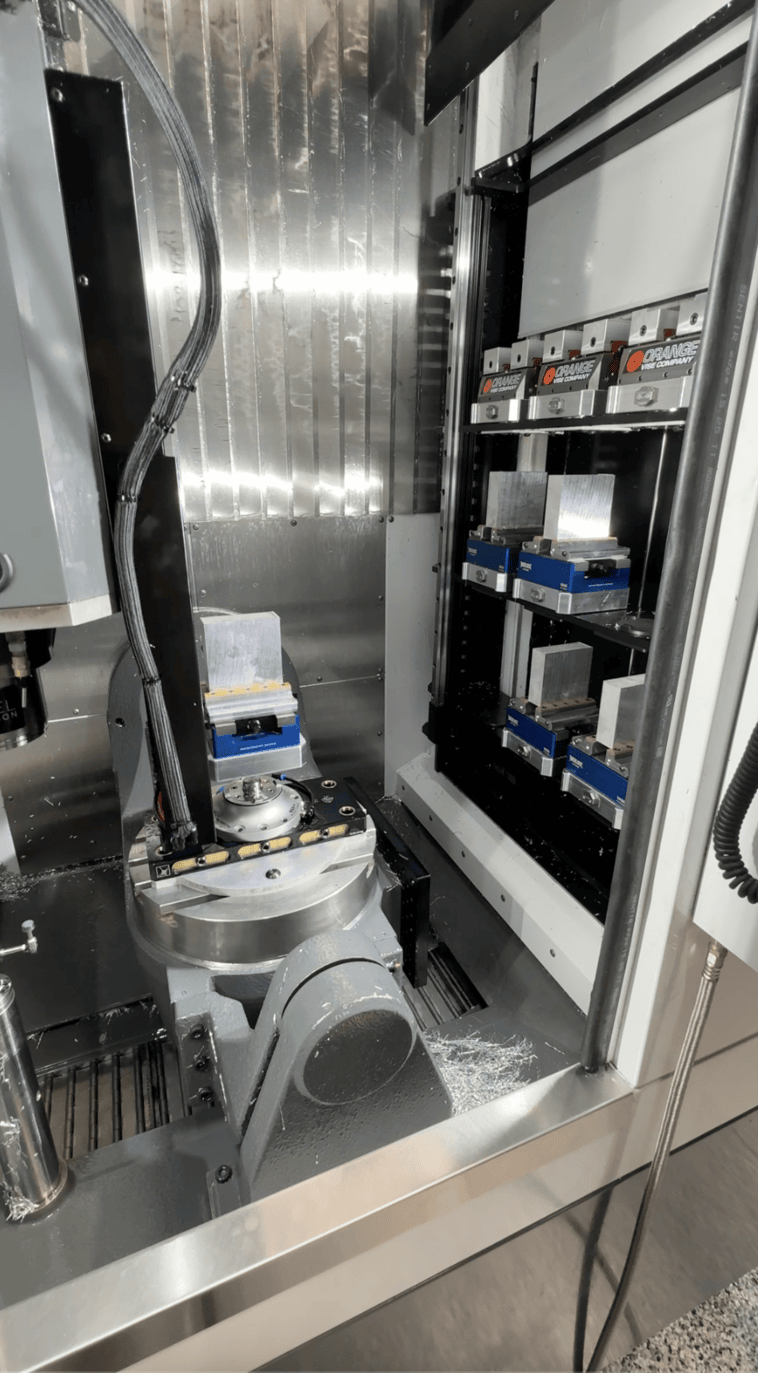

Gimbel Automation's Universal Gripper Plates are the gold standard for almost all parts that are rectangular or round when selecting fingers for air grippers. Thanks to their modular set of #10-24 holes, they can be adjusted for any part between a 1/2" and 4".

The Universal Gripper Plate set fits all Gimbel Automation CNC Spindle Grippers for CNC machine automation, and includes

- 2x Modular Gripper Finger Plates

- 8x #10-24 Threaded Anti-Marr Studs

- 2x Sets of Rubber Compression Pads

Pros:

- Great for regularly-shaped parts (round or circular)

- Included Fingers for Air Grippers: Included for free with all Gimbel Automation Grippers

- Rubber compression pads allow for Z preloading

Cons:

- Challenging to hold oddly-shaped parts

- Cannot be used for Flip Station

2. Flip Station Gripper Fingers

Gimbel Automation's Flip Station Gripper Fingers for Gimbel's Flip Station (consisting of a base and air gripper) are the easiest way to flip your component 180 degrees for machining the second op in a machine tending automation cell.

Unlike other Flip Station solutions on the market, Gimbel utilizes the "top-hat" that is inherently present on all two-operation components being CNC Machined.

Slots in the Gripper Fingers on either side are combined with a quick-adjust backer plate to allow the completely modular adjustment for various workpieces.

This is the ideal Finger for Air Grippers being used in the Flip Station configuration.

Pros:

- Works on virtually any two-operation component at the Flip Station

- Easy modular quick-adjust system adapts to a wide range of part sizes

Cons:

- Difficult to use in applications outside of the Flip Station

- Difficult to use on parts that do not have a top-hat

3. Premium Gripper Fingers

Gimbel Automation's Premium Gripper Fingers are an excellent solution when you have custom components with a unique geometry, or clearance issues that need to be overcome.

While they are similar to the Flip Station Gripper Fingers for Air Grippers discussed above, they do not have the "top-hat" slots, and are intended to be machined by the end user for their specific application.

Pros:

- Custom-Made: Can achieve virtually any task that is required by the user

Cons:

- Upfront Effort: Custom nature requires design and manufacturing by the end user

4. Custom Gripper Fingers

Gimbel Automation's wide selection of gripper fingers for air and coolant grippers is almost always sufficient to handle your air gripper needs.

However, there are many cases where it makes sense to make custom grippers. These grippers can often be 3D printed, and have the advantage of being able to easily manufactured and conform to virtually any material.

Pros:

- Easy Adjustment: adjust each finger effortlessly with two front-facing screws.

- Fully-Machinable: Machine the blank gripper fingers to perfectly conform to your unique parts.

Cons:

- Upfront Effort: Must machine fingers to conform to unique parts

- Overall Length: Premium gripper fingers are longer than their traditional counterparts

Gripper Fingers for Air & Coolant Grippers

Frequently Asked Questions

What is a Finger for Grippers Used For?

A finger for air grippers is the part of the gripper that interacts with the component or part to be manipulated by the gripper.

What is the best Finger for my Application?

If possible, we generally recommend using the Gimbel Automation Universal Gripper Plate Fingers for most parts. For Flip Stations, we recommend using the Flip Station Fingers.