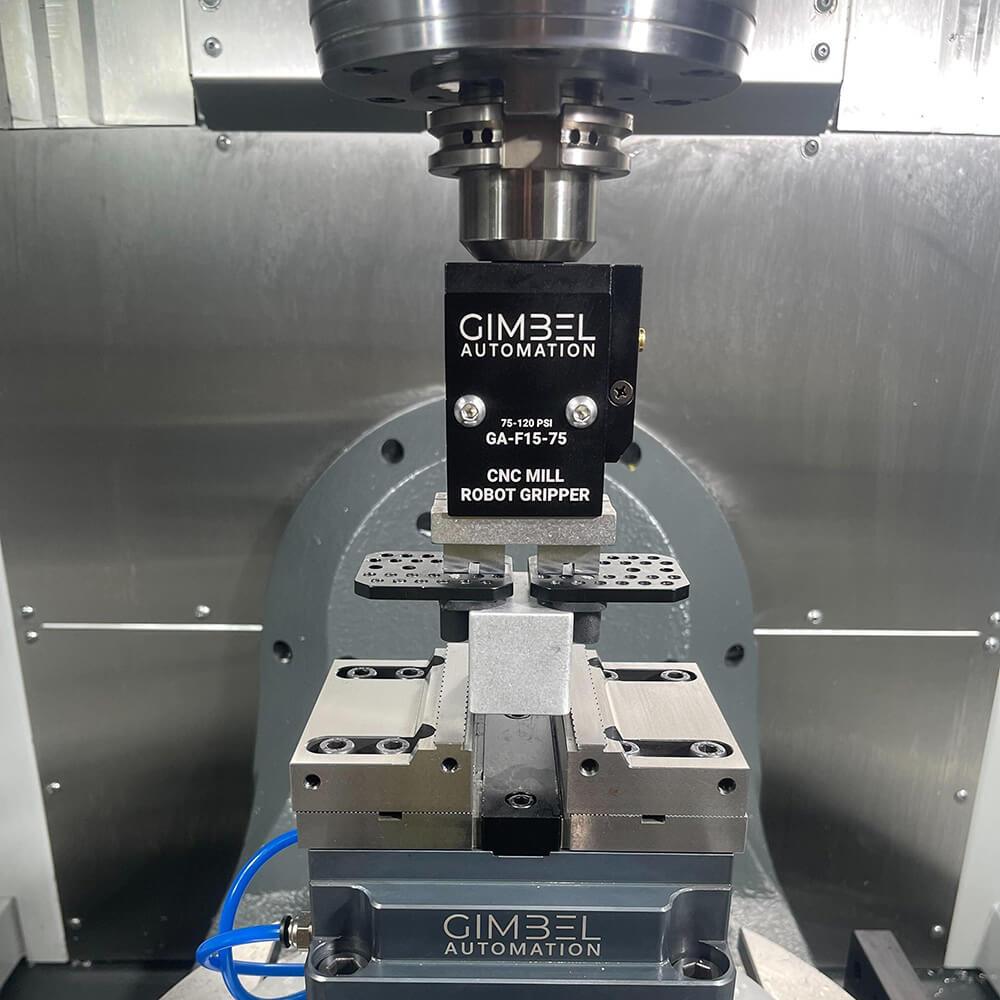

TSA (Air) GimGripper4™ – Universal CNC Spindle Gripper for Through-Spindle Air Machines

-

Need Turnkey CNC Automation?

For Turnkeys and Custom Applications, we can help!

- Book a Turnkey Demo

Description

Our Through-Spindle Air (TSA) GimGripper4™ is the go-to in-machine CNC automation solution for machine-tending on CNC machines equipped with Through-Spindle Air. The CNC Spindle Gripper installs into the machine’s automatic tool changer (ATC) just like any other tool, transforming your CNC into a reliable part-loading system without the need for costly robotic automation.

This fourth-generation GimGripper™ delivers extended life — now up to 2,000,000 actuations, with maintenance recommended every 250,000 cycles — making it one of the most durable spindle grippers for CNC automation on the market.

How It Works

Once a piece of stock is ready to load, the gripper is automatically called from the ATC, the machine positions over the stock, and the CNC spindle gripper clamps securely. The GimGripper’s fingers are Normally Open and close using Through-Spindle Air, ensuring simple, reliable operation for high-volume CNC machining.

Complete Ready-to-Run Kit

Every GimGripper4™ ships as a complete spindle gripper kit, ready for production use:

- FastFinger™ Universal Plates – enable fast setup for a wide variety of part sizes

- Rubber Compression Pads – allow preloading in the Z-Axis for excellent part repeatability without excessive spindle bearing load

- 3/4″ Shank with screw-in extension – flexible integration into your CNC machine

Easy CNC Integration

- Integrate M-Code pneumatic control using our MCodeAir™ Kit (add the 24V Converter Kit for Brother, Fanuc, Hurco, or cobot applications)

- Pair with AutoVise™ Pneumatic CNC Vises such as the 75 mm AutoVise for secure in-machine clamping

- Automate second operations with the GripFlipGrip5™ Two-Op Module or compact GripFlipGrip-Mini™

- Add the QuickFlip180™ Pneumatic Part Flipper to fully automate part flipping between operations

Options for Non-TSA Machines

For CNCs without Through-Spindle Air or Coolant, choose our Roto-GimGripper™, which passes air in through the FloLink™ manifold block for seamless integration.

Why Choose the GimGripper4™?

- A cost-effective CNC automation solution compared to robotics from Schunk or Fastems

- Built for production machine shops in aerospace, defense, and medical industries

- Eliminates labor bottlenecks and reduces downtime in high-volume CNC operations

- Designed and supported in the USA

Technical Specs & Downloads

Technical Specs

| Technical Specs | |

|---|---|

| Pressure Range | 0-140 psi |

| Repeatability | +/- 0.001” |

| Part Size Grip Range | 0” – 4.125” |

| Recommended Part Weight | <10 lbs |

This gripper works out of the box with your Through-Spindle Air machine, and only takes up one tool-slot. Works with almost all tool changers.

FAQs

CNC Spindle Grippers, also known as CNC Spindle Grabbers or CNC Part Tending Grippers, are the most cost-effective and easiest-to-implement form of CNC Machine Tending Automation. Unlike many other forms of Machine Tending Automation, CNC Spindle Grippers are the only form of CNC Machine Tending Automation that uses your CNC Machine itself to accomplish the movement of your components to be machined into and out of the workholding.

CNC Spindle Grippers are there to free up machine operators and let the machine tend itself automatically. Instead of eating up an operator’s entire day loading and unloading parts, the CNC Machine itself is able to load and unloads its own components, allowing operators to focus on process improvements, QC, and programming. While no form of CNC Machine Tending Automation eliminates the need for skilled operators, CNC Spindle Grippers often allow an operator to monitor and maintain five to six machines instead of only one.

Programming your CNC Spindle Gripper for Automated Machine Tending is surprisingly easy. Check out our Programming Article for complete instructions. Since this was the biggest hurdle for our customers, we created a Program Generator to allow you to generate programs fully-automatically for single operation machine tending automation. For two-operation automation, such as what you might use with our Two-Op Automation Pallet, we provide you with a free comprehensive template, which makes programming parts to run fully automatically as simple as programming a single two-operation part.

We make a variety of CNC Spindle Grippers including:

- Patent-Pending Bypass Model for Haas Mills (CAT40)

- Patent-Pending Rotary Bypass Model for Haas, Brother, & Robodrills (CAT40 & BT30)

- 3/4" Through-Spindle Coolant Model

- 3/4" Through-Spindle Air Model

Our 3/4" Through-Spindle Coolant and 3/4" Through-Spindle Air models can use any type of tool-holder. The 3/4" TSA Model can use any holder out-of-the-box. The 3/4" TSC Model can use any holder, but may require drilling a hole into the side of the holder to allow coolant depressurization.

Our Patent-Pending Rotary Bypass models are the only solution on the market that allow you to use Spindle Grippers for Machine Tending on a machine that lacks Through Spindle Air or Through Spindle Coolant.

Our Grippers are strategically size to work in almost any tool-changer without taking up more than a single tool-slot. We’ve tested hundreds of machines from Haas, Doosan/DN, Brother, Fanuc, DMG Mori, Hermle, Okuma, and many others. For the vast majority of Side-Mount and Umbrella tool-changers, these Grippers are tested and verified. For odd-ball tool-changers such as side-mount chain-style ATC’s, contact us to confirm compatibility.

Yes, you can do this with our Rotary Bypass Grippers, our Through-Spindle Air Grippers, or our Through-Spindle Coolant Models.

Gripper-loaded part weight essentially unlimited (to a point) depending on the finger design. We’ve had customers 3D print or machine custom fingers that hook under the part for large part loads.

For most applications (with the standard included gripper fingers), we generally recommend keeping part weight below 5 lbs for gripper part handling.

We’ve had customers move as much as 10lbs with the default gripper fingers, but you need to use 150-200psi air to make sure things are very tightly held. We’ve had customers move as much as 45 pounds using custom gripper fingers that wrap around the bottom of components.