Explore AI Summary

Welcome back to the Gimbel Automation Blog! Today, we delve deep into the world of CNC machining and explore advanced techniques that can take your automation game to the next level. Whether you’re a seasoned manufacturer or just starting to embrace CNC automation, this guide is tailored to help you master the art and science of precision machining.

Understanding the Basics: CNC Machining and Automation

Before we jump into advanced techniques, let’s ensure we’re all on the same page. CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. When integrated with automation, CNC machines can perform complex and precise operations with minimal human intervention, resulting in increased efficiency, accuracy, and consistency.

Advanced Automation Techniques for CNC Machining

- Adaptive Machining. This technique involves real-time control and adjustment of the machining process. By using sensors and feedback systems, the CNC machine can adapt to variances in the material or tool wear, ensuring consistent quality and precision.

- High-Speed Machining (HSM). HSM focuses on increasing cutting speeds and feed rates to boost productivity and reduce cycle times. Implementing HSM requires a deep understanding of tool paths, material properties, and machine dynamics.

- Five-Axis Machining. This advanced method allows the workpiece to be manipulated five different axes simultaneously, providing incredible flexibility and precision. It’s particularly useful for complex parts that would otherwise require multiple setups.

- Tool Management and Optimization. Efficient tool management is crucial in automated CNC machining. Advanced systems can monitor tool wear and life, automatically swapping out tools when necessary and ensuring optimal performance.

- Data- Driven Manufacturing. Efficient tool management is crucial in automated CNC machining. Advanced systems can monitor tool wear and life, automatically swapping out tools when necessary and ensuring optimal performance.

Harnessing the Power of Automation with Gimbel Automation

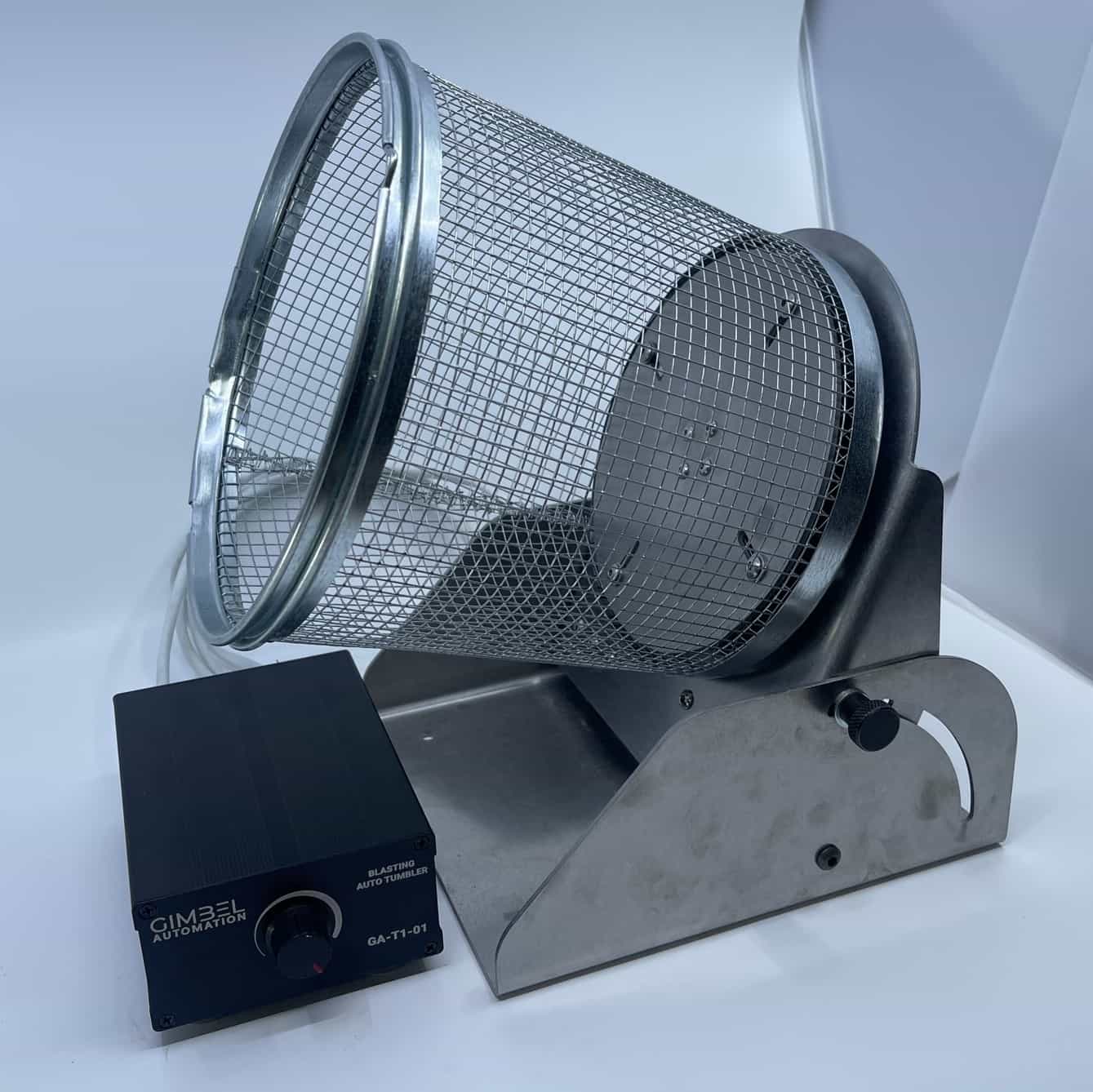

At Gimbel Automation, we are at the forefront of in-machine automation, providing innovative solutions tailored for the CNC machining industry. Our range of products, including CNC Spindle Grippers, Air Vises, and complete turn-key automation systems, are designed to seamlessly integrate with your CNC machines, propelling your operations to new heights.

Implementing Automation with Gimbel Automation

- Consultation and Customization: Reach out to our team for a comprehensive consultation. We will analyze your specific needs and provide tailored automation solutions.

- Training and Support: We believe in empowering our clients. Our team offers extensive training and support, ensuring you and your staff are well-equipped to maximize the benefits of our automation products.

- Continuous Improvement: Automation is an ongoing journey. We are committed to innovation and continuously strive to enhance our products and services, ensuring you stay ahead of the curve.

Mastering advanced automation techniques in CNC machining is a surefire way to enhance precision, efficiency, and productivity. With Gimbel Automation as your partner, you have access to state-of-the-art solutions and a team of experts dedicated to your success.

Are you ready to elevate your CNC machining and unlock unparalleled precision and efficiency? Contact Gimbel Automation today, and let’s start your journey towards mastering automation in CNC machining.

Discover Advanced Automation Solutions

#instamachinist #cnc #cncmachine #cncmachining #robots #manufacturing #gimbelautomation