Explore AI Summary

Navigating the array of material options for CNC machining is a critical step towards ensuring the success of your manufacturing projects. The material you select directly impacts the performance, aesthetic appeal, and durability of the finished parts.

Aluminum, Brass, and Copper: The Trio of Versatility

- Aluminum: Known for its excellent machinability, aluminum is lightweight yet strong, making it ideal for aerospace and automotive applications. Its ability to conduct heat and electricity also makes it suitable for electronic components.

- Brass: This alloy stands out for its corrosion resistance and aesthetic appeal, particularly in decorative and architectural applications. Its low friction coefficient makes it a choice material for gears and bearings.

- Copper: Renowned for its thermal and electrical conductivity, copper is frequently used in electrical components and heat exchangers. Its antimicrobial properties also lend to medical applications.

Stainless Steel: Durable and Corrosion-Resistant

- Challenging yet rewarding to machine, stainless steel is a go-to for parts requiring high strength and resistance to heat and corrosion. It's widely used in medical devices, food processing equipment, and marine applications.

Plastics and Composites: Versatile, Light and Cost-Effective

- Plastics like ABS, polycarbonate, and PEEK offer various degrees of strength, flexibility, and temperature resistance, making them suitable for a wide range of applications from consumer products to automotive components.

- Composites, combining plastics with fibers like glass or carbon, offer enhanced properties like increased strength or reduced weight, essential in aerospace and automotive industries.

Material Selection Across Industries

Different industries have specific requirements that influence material choice. In sectors like aerospace, automotive, or medical, materials must adhere to strict standards and regulations. Tailoring your selection to these unique industry needs is essential for optimal performance.

Choosing the Right Material for Your Application

Beyond physical properties, factors like material availability, cost, and environmental impact play a role in decision-making. Recycled materials and sustainable sourcing are increasingly important considerations in material selection. Consider the intended use of the part, exposure conditions, and required tolerances to ensure you select the most appropriate material.

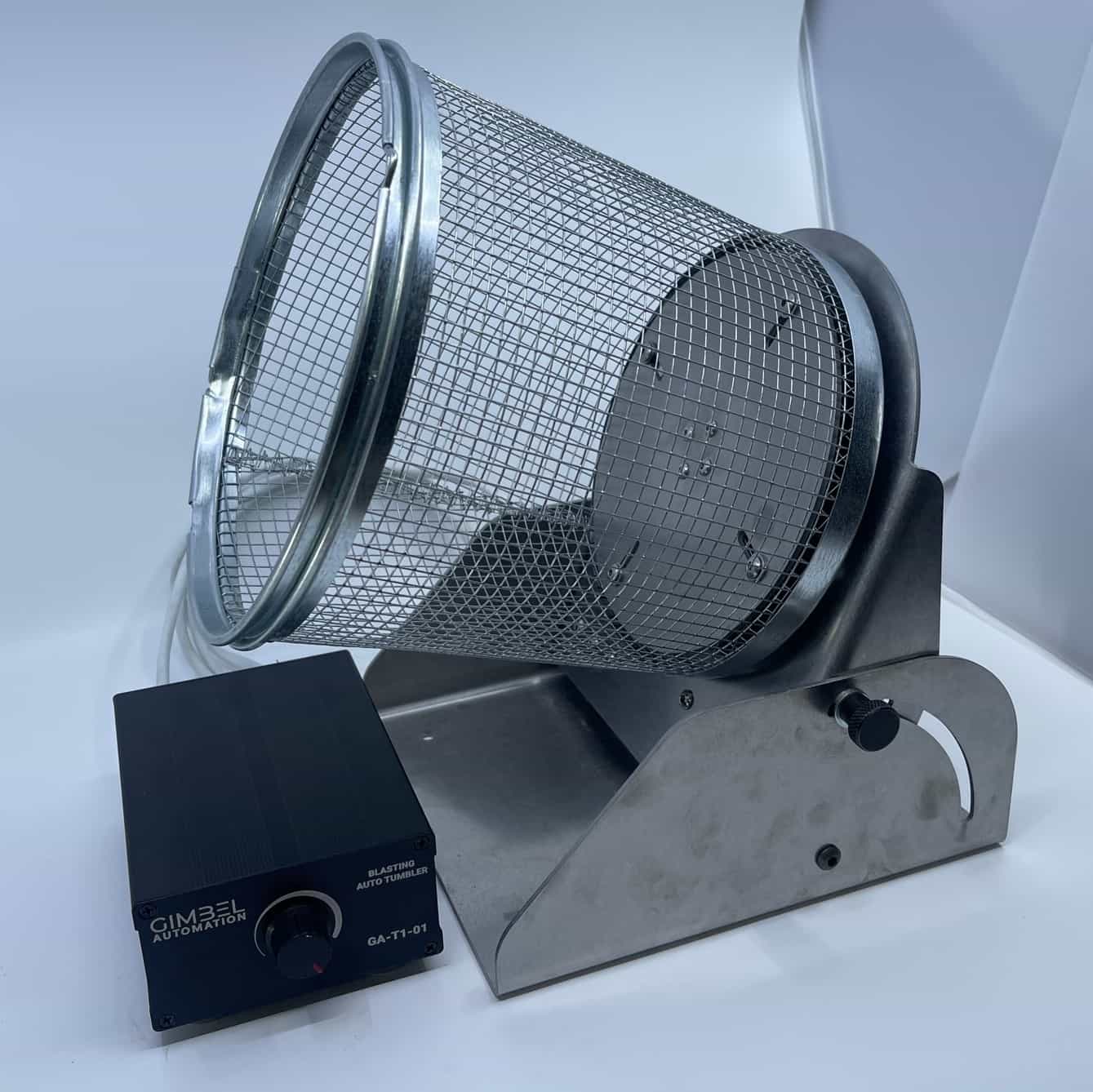

Consultation and Expertise at Gimbel Automation

At Gimbel Automation, our team brings expertise in material selection for CNC machining. We are here to assist you in navigating these important decisions, helping you to achieve the best possible outcomes for your CNC projects.

Elevate your CNC machining projects with informed material choices. Connect with us at Gimbel Automation for guidance and support in this critical aspect of your production process.