Explore AI Summary

Welcome to the latest Insights from Gimbel Automation. In this edition, we delve into a crucial topic for modern manufacturers: determining the optimal time to embrace CNC automation. This newsletter is dedicated to providing you with comprehensive insights and strategies to guide you through this critical decision-making process.

Evaluating Your Production Landscape

The transition to CNC automation begins with an in-depth analysis of your existing production setup. Key indicators for considering automation include:

- A rising demand for enhanced precision in your products

- Increasing production volumes surpassing the capacity of manual operations

- The necessity for consistent quality in output

- Identification of repetitive tasks that could benefit from automation

These factors are instrumental in determining whether your production process is ready for an automation upgrade.

Conducting a Thorough Cost-Benefit Analysis

Investing in CNC automation requires a strategic approach. A detailed cost-benefit analysis is essential, taking into account the initial investment and juxtaposing it with the long-term advantages like improved operational efficiency, reduced manual errors, and savings on labor costs.

Growth Trajectory and Automation

As your business expands, the efficiency of your production methods should evolve accordingly. Automation serves as a powerful tool for scaling up production capabilities, facilitating the management of increased demand without compromising on the quality or consistency of your products.

The Imperative of Consistency and Precision

In sectors where precision is paramount, the role of automation cannot be overstated. CNC automation brings a level of repeatability and accuracy that is vital for maintaining high standards of production, especially in high-volume environments.

Addressing the Skills Shortage in Manufacturing

The challenge of a skills gap is prevalent in many sectors of manufacturing. CNC automation offers a viable solution, taking over complex, skill-intensive tasks and allowing your workforce to concentrate on more strategic aspects of production.

Embracing a Future-Ready Approach

The integration of CNC automation is not just about meeting current needs but preparing for the future. Keeping pace with technological advancements in automation is crucial for maintaining a competitive edge in an ever-evolving industry.

Guidance for the Transition

Making the move to CNC automation is a significant decision. It necessitates a deep understanding of your current operations, industry trends, and long-term business objectives.

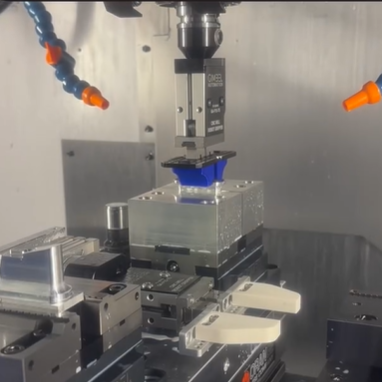

Tailoring Automation to Fit Your Unique Needs with Gimbel Automation

At Gimbel Automation, we specialize in creating customized automation solutions that cater to the specific needs of your manufacturing operations. We understand that each setup has its unique challenges and requirements. Whether it involves customizing material handling, integrating specialized software, or configuring machinery for specific tasks, our team is committed to developing solutions that perfectly align with your production goals and enhance your operational efficiency.