Introduction

Every machine shop and production floor has the dream of a smooth and automated production of their parts and products. But actually successfully implementing automated CNC Machine Tending for CNC Vertical Mills is usually an intimidating and expensive task. CNC stands for computer numerical control, which refers to the automated control of machining tools and 3D printers by means of a computer, streamlining manufacturing processes such as loading raw materials and maintaining operational efficiency.

There are also numerous different approaches to Automated CNC Machine Tending, including Automatic Pallet Loading, Pallet-Changing Robot Cells, Cobots, and CNC Spindle Gripping just to name a few. Depending on the type of parts and automation selected, CNC Machine Tending for vertical CNC Mills can range in price from $4,500 for One-Operation CNC Spindle Gripper System all the way up to $250,000 or more for a integrated pallet-changing or robot-cell system. Traditionally, machine tending has relied on manual labor, which is susceptible to human error and can negatively impact consistency and quality in manufacturing.

In this article, we’ll discuss the various types of automation, and more specifically how CNC Spindle Gripper Automation can offer you unprecedented ROI compared to traditional CNC Machine Tending Automation Solutions.

Table of Contents

- Introduction

- Is CNC Machine Tending right for me?

- Why is CNC Machine Tending Important?

- How Can CNC Tending Benefit Your Shop?

- Do I Need CNC Machine Tending Automation?

- Improve Efficiency and Productivity

- Address Labor Challenges

- Enhance Production Capabilities

- There is no faster way to grow and increase profits than automation in the manufacturing industry.

- 1. CNC Spindle Gripper Machine Tending

- 2. "Robot-in-a-Box" Machine-Tending Cells

- 3. Collaborative Robot (”Cobot”) Part-Loading

- More About spindle gripper cnc automation

- How It Works: CNC Spindle Gripper Machine Tending

- Safety Considerations for Automated Machine Tending

- Maintenance and Repair of Automated Machine Tending Systems

- Real-World Examples of Automated Machine Tending

Is CNC Machine Tending right for me?

Why is CNC Machine Tending Important?

You probably want to invest in CNC Machine Tending if:

You want to allow a single operator to run five or more machines instead of one

You want to get the most out of your capital investment through “lights-out” production

You’re having a hard time finding qualified and dedicated machine operators

You want to minimize your labor costs and maximize your production

You can’t keep up with your current production demands

You have low Spindle-Utilization percentages because of long part-loading times

Allowing manufacturers to implement robotic machine tending not only increases productivity and increases throughput, but also improves efficiency, precision, and safety. This is especially important in industries like automotive manufacturing, where robotic machine tending is widely used to streamline production processes and ensure high-quality output.

How Can CNC Tending Benefit Your Shop?

1. Boost Your Production Throughput

While many people outside the industry think that CNC Machine Tending will take away jobs, most people in the industry know that, in actuality, it’s quite difficult to keep up with demand. Moreover, to be profitable in North America as a Machine Shop or Production Facility, increasing labor and vendor costs are making it a necessity to have a single operator monitor and run three, four, or even five machines. This directly correlates to increased production output. Automated machine tending systems, such as those using FANUC robots, can operate continuously without fatigue, which helps increase throughput and leads to increased performance in manufacturing operations.

2. Boost Your Profits

In this industry, another difficult reality is that Monetary Capital is usually the biggest constraint: the CNC Machinery usually costs at least $75,000 per spindle. Getting the most out of that tied up capital on the shop floor also incentivizes companies to run two to three shifts, since it means that your spindle can be running 24 hours a day.

Because you are now making more parts with the same operators running multiple machines, and with the machines now running longer hours unattended, automation almost always leads to increased profits in the long-run. Gimbel’s approach to in-machine Automation can often result in ROI in as little as two weeks. Robotic machining solutions, especially when integrated with digital twins for virtual testing, can deliver rapid ROI—often within 12-18 months—by significantly increasing efficiency and reducing setup times by up to 40%.

3. Better Allocate Your Labor Pool

Here’s something that you, a Machine Shop Owner or Production Floor Manager, already know: finding good people is hard. Finding great and reliable operators to work a job that involves loading and unloading parts all day is even harder.

That’s why automation is critical to competing in the machining industry in North America. By leveraging one operator to run up to five machines, you can remain competitive, as well as allocate your talented staff where they’re needed the most.

Integrating robots into CNC machine tending helps alleviate the burden on human workers by taking over repetitive and labor-intensive manual tasks. This allows human workers to focus on other tasks that require higher skill and attention, improving job satisfaction and making better use of your team’s expertise.

Do I Need CNC Machine Tending Automation?

You probably want to invest in CNC Machine Tending if:

You want to allow a single operator to run five or more machines instead of one

You want to get the most out of your capital investment through “lights-out” production

You’re having a hard time finding qualified and dedicated machine operators

You want to minimize your labor costs and maximize your production

You can’t keep up with your current production demands

You have low Spindle-Utilization percentages because of long part-loading times

Manual machine tending is labor-intensive, prone to human error, and limited by operator fatigue or shift changes. These drawbacks make automation with CNC machine tending a more attractive and efficient solution.

What Are Some Other Reasons to Consider CNC Machine Tending Automation?

Improve Efficiency and Productivity

Run Multiple Machines: Enable a single operator to oversee five or more machines, increasing productivity without expanding your workforce.

Maximize Investment: Achieve optimal returns on your capital investment through “lights-out” production, allowing machines to operate autonomously even during off-hours.

Address Labor Challenges

Overcome Labor Shortages: Struggling to find skilled machine operators? Automation can bridge this gap, ensuring continuous operation despite staffing challenges.

Reduce Labor Costs: By minimizing the need for manual intervention, you can significantly lower labor costs and streamline your workforce.

Enhance Production Capabilities

Meet Production Demands: If you’re struggling to keep up with current production requirements, automation can help scale your operations efficiently. Automated systems efficiently handle raw material loading and the removal of completed parts, with robots performing these repetitive tasks with high precision and consistency, thereby reducing human error.

Boost Spindle Utilization: Reduce long part-loading times that negatively impact spindle utilization, ensuring your machines run at peak performance.

There is no faster way to grow and increase profits than automation in the manufacturing industry.

Types of CNC Machine Tending Systems

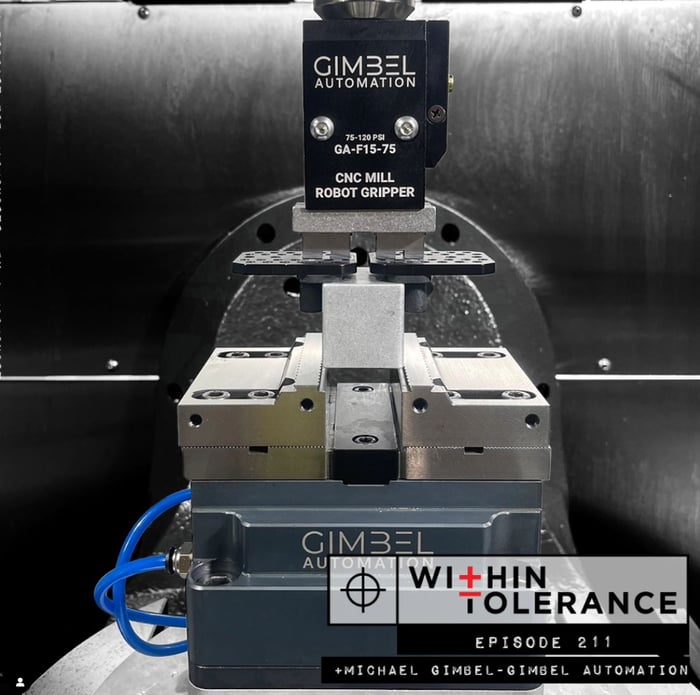

1. CNC Spindle Gripper Machine Tending

CNC Spindle Gripping is one of the industry's best-kept secrets for CNC Machine Tending. While it's been used at the biggest companies including Kennametal, Parker Hannifin, and countless Tier 1 Automotive Suppliers, CNC Spindle Gripping has historically been unknown to small and midsized manufacturers.

CNC Spindle Gripper Automatic Machine Tending differs from other Machine Tending in its simplicity: rather than interface with an external robotic system, CNC Machine Tending uses the CNC Vertical Mill already on your shop floor as the Automation itself. It's actually quite intuitive if you take a moment to think about it: your CNC Vertical Mill can already move in at least three-axes, so why not use that movement to handle the part-tending instead of an operator?

CNC Spindle Gripper Systems for Automated Machine Tending involve two key components: a CNC Spindle Gripper and a form of Automated Workholding. More advanced systems can also include a way to flip the component so that multiple operations can be completed in a single cycle. The system operates with the CNC Spindle Gripper being loaded into the machine spindle like any other tool from the tool-changer, and that Spindle Gripper than grabs onto a part from a tray affixed to the machine table or from a loading conveyor.

2. "Robot-in-a-Box" Machine-Tending Cells

Part-Loading Robot CNC Cells

Commonly referred to as a “Robot-in-a-Box”, Robot CNC Cells include systems from the likes of Automation Within Reach and many other systems that center around a robot from Fanuc, Universal Robots, or many other brands.

Pallet-Loading Robot CNC Cells

The key difference between Part-Loading and Pallet-Loading Robot Cells is exactly as you would assume: instead of exchanging individual parts, the Robot Cell is exchanging entire pallets consisting of one or more pieces of stock already in workholding. Examples of popular Pallet-Loading Robot Cells include Halter Robotics and Trinity Robotics.

The Pallet itself can be as large as the entire machine table, or as small as an individual Erowa or System 3R pallet that holds a singular component to be machined. These pallets almost always interface with an automated Zero-Point Pallet System that securely holds the entire pallet and allows the very precise and automatic location of the pallet for every single loading cycle.

3. Collaborative Robot (”Cobot”) Part-Loading

While there are many systems that use Fanuc or Kuka industrial robots in caged-off machine cells, the innovation of Collaborative Robots has enabled Cobots to see more and more use in machine shops and Production Floors across the United States.

While it usually doesn't make sense to Pallet-Load using Cobots, Part-Loading with them can be an excellent solution for many shops. Since they don't need safety cages or light-curtains to prevent workplace accidents, the robot can be setup to load and unload individual pieces of stock.

The biggest downside of cobots include the initial system cost and the difficulty of implementation. While the robots are supposed to be easy to “train”, it is still an extra step to be carried out for each and every different part that you want to automate. In reality, Cobot integration is almost never as easy as it seems, and the vast majority of shop floors opt to hire a Systems Integrator to work out the details and integrate the system for them.

A good rule of thumb for a mid-tier Cobot Integration is to spend $50,000-$75,000 on the Cobot and peripherals, and to budget $35,000-$50,000 for the System Integration process.

More About spindle gripper cnc automation

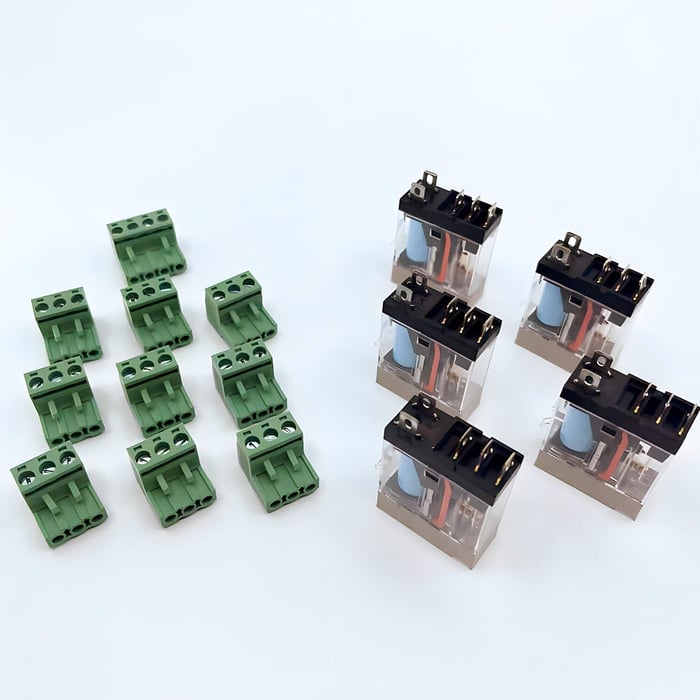

Components of CNC Spindle Gripper Systems

1. The CNC Spindle Gripper

The CNC Spindle Gripper is an automation tool for CNC Machine Tending that loads into the machine spindle like any other tool. It can grab and release parts, and changes in the machines automatic tool-changer (ATC).

2. Automated Workholding

Of course, you need a way to hold your parts during the machining process, so you'll need to use an automated vise.

3. Accessories & Advanced Features

For more advanced customers, products like our Part Flip Station or our Two-Operation Automation Pallet can allow complete single-piece flow and automated production.

How It Works: CNC Spindle Gripper Machine Tending

The gripped part is placed into the automated vise, and the part is then machined in-place. Once the part is finished its first operation, it is either put back in the tray or loading conveyor’s outfeed, or continues automatically to be regripped, flipped, and automatically machined for any other ops. The system can also handle completed parts, ensuring efficient removal and handling of finished products. Additionally, it is capable of performing secondary operations, allowing for future expandability and increased productivity. The role of a machine tender includes monitoring the machine's performance, conducting quality checks, and ensuring that the production process runs smoothly.

There are two key advantages to CNC Spindle Gripping over other CNC Machine Tending automation solutions:

CNC Spindle Gripper systems are extremely cost-effective. A typical One-Operation package can be purchased for less than $5,000, and a typical Two-Operation package can be purchased for less than $10,000. This results in extremely fast return-on-investment.

CNC Spindle Gripper Automation is by far the easiest Machine Tending system to implement. Since the programming and math is done exclusively on your CNC machine’s existing control, there is no robot to train, no complex hardware to integrate, and no overhaul of your existing programming workflow.

Safety Considerations for Automated Machine Tending

When introducing automated machine tending solutions into your production environment, safety should always be a top priority. Automated systems, including robotic arms and other advanced technologies, are designed to minimize the risks associated with operating CNC machines, injection molding machines, and other heavy machinery. By automating repetitive tasks such as loading and unloading, manufacturers can significantly reduce the exposure of human operators to hazardous conditions, including moving parts, sharp tools, and high temperatures.

To ensure a safe working environment, it’s essential to implement robust safety protocols. This includes installing physical guards around automated machine tending systems, integrating safety sensors that can detect the presence of human operators, and establishing clear emergency stop procedures. Comprehensive training for staff is also crucial, so everyone understands how to interact safely with both the automated machine and the surrounding equipment.

Regular maintenance of automated systems is another key aspect of safety. Well-maintained robotic machine tending solutions are less likely to malfunction, which helps prevent accidents and keeps productivity high. By prioritizing safety in every aspect of your machine tending operation, you not only protect your workforce but also ensure the smooth, uninterrupted operation of your CNC machines and other automated equipment.

Maintenance and Repair of Automated Machine Tending Systems

Keeping your automated machine tending systems in top condition is essential for maintaining continuous operation and maximizing the return on your investment. Regular maintenance routines should include cleaning and lubricating robotic arms, updating software, and running diagnostic checks to catch potential issues before they lead to downtime. For CNC machines and other equipment integrated with your automated machine tending solution, scheduled inspections, part replacements, and precise calibration are necessary to maintain accuracy and reliability.

A proactive maintenance plan not only extends the lifespan of your automated systems but also helps reduce labor costs by minimizing unexpected breakdowns and the need for manual intervention. In the event of a malfunction, having a clear repair strategy—whether through in-house expertise or partnerships with equipment manufacturers—ensures that your production process gets back on track quickly. Training your team in basic troubleshooting and repair techniques can further reduce downtime and reliance on external support.

By investing in regular maintenance and prompt repairs, manufacturers can improve overall equipment effectiveness, keep production running smoothly, and achieve the full benefits of their automated machine tending investment.

Real-World Examples of Automated Machine Tending

Across the manufacturing industry, automated machine tending has become a game-changer for companies seeking to boost productivity, reduce labor costs, and maintain consistent quality. In the automotive sector, for example, robotic machine tending solutions are widely used to load and unload parts from CNC machines, resulting in faster cycle times and higher-quality finished products. Aerospace manufacturers rely on automated systems for the precise handling of complex components, ensuring that every finished part meets strict regulatory standards.

Job shops and contract manufacturers have also embraced automated machine tending to handle a diverse range of parts and materials. This flexibility allows them to quickly adapt to changing market demands and maintain a competitive edge. The integration of collaborative robots, or cobots, has further expanded the possibilities for machine tending applications. These robots can safely work alongside human operators, taking on repetitive machine tending tasks such as loading and unloading machines, managing raw materials, and handling finished parts.

By automating these processes, manufacturers free up their skilled workforce to focus on higher value tasks like programming, quality control, and process optimization. The result is increased productivity, reduced labor costs, and improved product quality—key advantages that help businesses achieve their production goals and thrive in a rapidly evolving market.