- Product Lines

-

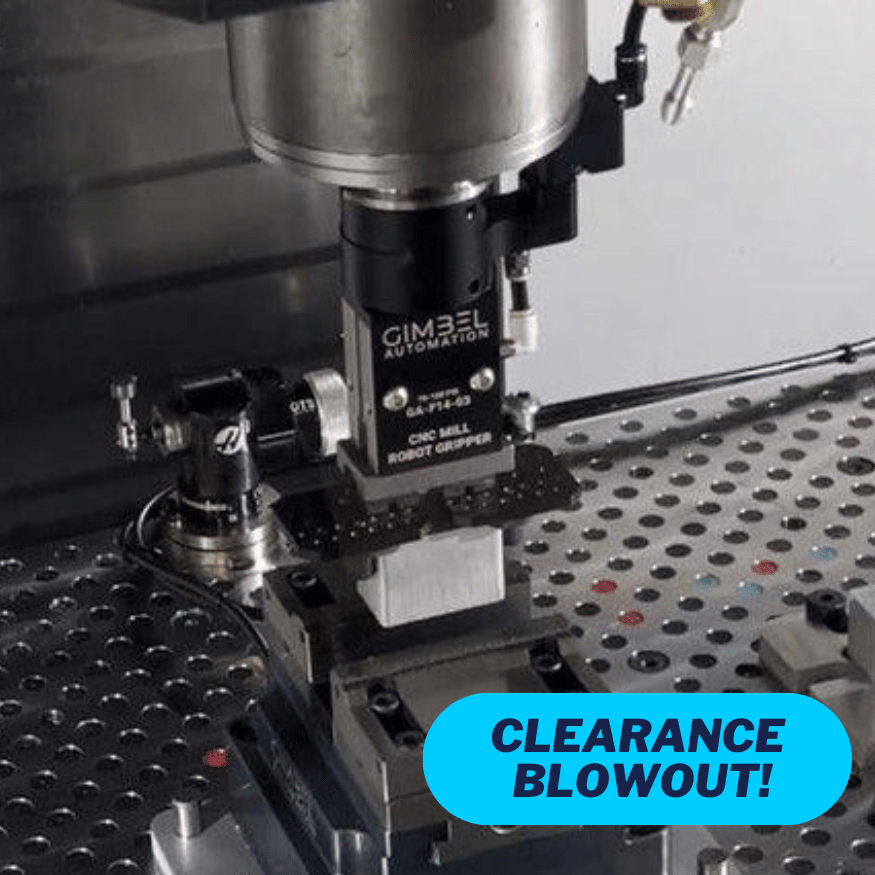

IntraLoad™ Pallet Changer

The faster ROI pallet automation system

GripFlipGrip™ Modules

Easy two-op single cycle automation

Two Op Bundles

Complete two-op Automation Kits

One Op Bundles

Complete one-op automation kits

CNC Auto-Doors

Industrial CNC auto-doors for automation

QuickFlip180™ CNC Station

Flip parts for two-op automation -

Air CNC GimGrippers™

Universal for Through air machines

Coolant CNC GimGrippers™

Universal for TSC machines

FloLink™ CNC GimGrippers™

FloLink™ grippers that allow spindle orient

GimVac™ Vacuum Grippers

Load parts using vacuum

GripFlipGrip™ Modules

Easy two-op single cycle automation

QuickFlip180™ CNC Station

Flip parts for two-op automation -

75mm Air AutoVise™

Compact pneumatic self-centering vise

Rotary Air AutoVises™

CNC pneumatic vise for 4 & 5th axis

100mm Air AutoVise™

Mid-sized pneumatic self-centering vise

GripFlipGrip™ Modules

Easy two-op single cycle automation

150mm Air AutoVise™

Extra large pneumatic self-centering air vise

Vise Accessories

Jaws & accessories for your air vises -

MCodeAir™ Solenoid Kit

Integrate air products minutes

AxisAir™ Rotary Unions

Pass air lines through 4th & 5th axis platters

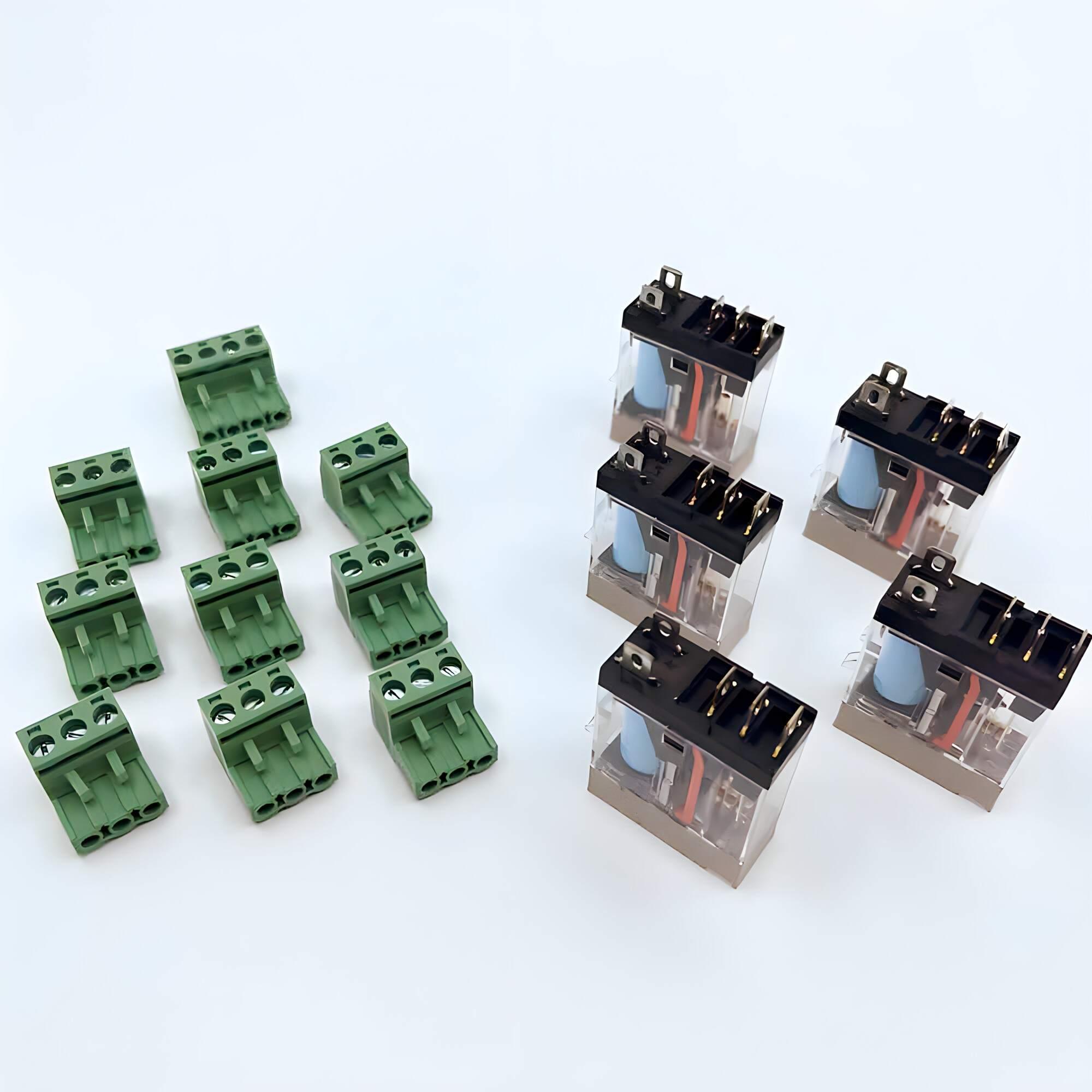

Haas Relay Kit

Enable your hass m-codes with this kit

Gripper Accessories

Make gripper integration even easier

Pressure Booster

Increase your grip force by boosting air pressure

OmniTube7™

Bundled air line for pneumatic automation -